- Products

- Technology

- Sustainability

-

-

Duracell Optimum

Duracell Optimum, our most groundbreaking innovation yet

-

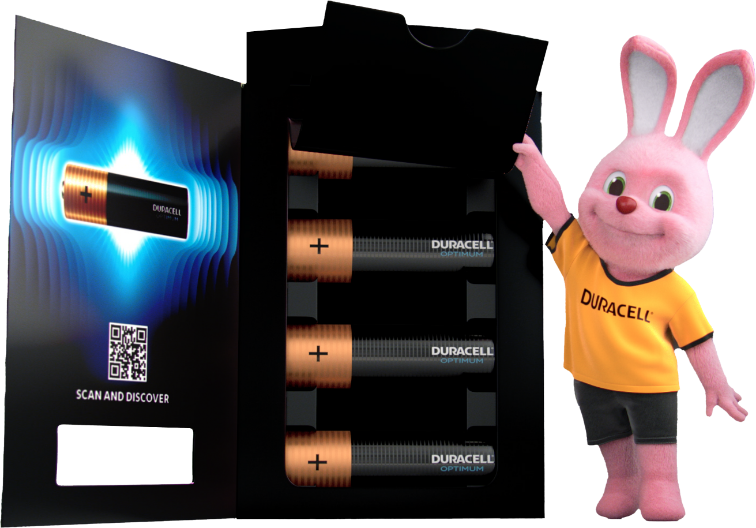

Lithium Coin Battery Safety

As lithium coin battery ingestion by babies or toddlers is a serious topic, it is important to learn about the…

- About us

-

Duracell Optimum

Select your region and language

Close- Pilas Duracell Argentina Argentina

- Duracell Batteries Australia Australia

- Duracell Batterijen België België

- Piles Duracell Belgique Belgique

- Pilhas Duracell Brazil Brazil

- Duracell Batteries Canada (English) Canada (English)

- Piles Duracell Canada (Français) Canada (Français)

- Pilas Duracell Chile Chile

- 金霸王 电池 中国 中国

- Pilas Duracell Colombia Colombia

- Duracell Batterier Danmark Danmark

- Duracell Batterien Deutschland Deutschland

- Pilas Duracell España España

- Piles Duracell France France

- Duracell Batteries India India

- Batterie Duracell Italia Italia

- デュラセルバッテリー 日本 日本

- Pilas Duracell México México

- Duracell Batterijen Nederland Nederland

- Pilas Duracell Perú Perú

- Baterie Duracell Polska Polska

- Bateriile Duracell Română Română

- Duracell Batteries Saudi Arabia Saudi Arabia

- بطاريات دوراسيل المملكة العربية السعودية المملكة العربية السعودية

- Duracell Batteries South Africa South Africa

- 듀라셀 배터리 대한민국 대한민국

- Duracell Piller Türkiye Türkiye

- Duracell Batteries United Arab Emirates United Arab Emirates

- بطاريات دوراسيل الإمارات العربية المتحدة الإمارات العربية المتحدة

- Duracell Batteries United Kingdom and Ireland United Kingdom and Ireland

- Duracell Batteries USA (English) USA (English)

- Pilas Duracell USA (Español) USA (Español)

Production

STRIVING TO REDUCE OUR

environmental impact

100% of Duracell plants in Europe run on Green Energy

Central EU location keeps transport distance short

Efficient container fill rate translates into lower emissions

-78%*

Carbon reduction

-24%*

Water consumption

-44%*

Gas consumption

*vs. 2014, Aarschot Plant.

Packaging

On a Mission To Be 100% Plastic Free

*except for our BabySecure Double Blister Pack where it serves the higher purpose of Child Safety

0

%of our primary & secondary cardboard packaging is made from recycled material

0

%of our cardboard packaging is fully recyclable

We’re proud to display the Nordic Ecolabel, one of the world’s hardest-won environmental certifications.

It certifies that our products are made in accordance with strict sustainable practices.

1

88% of all Duracell packaging in Western Europe is plastic-free**

**based on cells sold, and 80% of Duracell packaging across all Europe & Africa, strong reduction plans in place to achieve plastic-free goal

2

Our cardboard packs are made from recycled material and are fully recyclable.

3

Child Safety is 1st priority. Our Lithium Coin pack features a secure Double Blister made from recycled PET***, so children can’t access the cell and potentially swallow.

*** All Duracell blisters are made from PET

Helping you recycle with innovative packaging

- Collection Box for empty cells

- Reminds consumers to recycle batteries

- Indicator how to place empty cells

- Constructed from recycled material & fully recyclable

Product

Product innovation also helps us lower our footprint

Introducing Duracell Optimum

Our long lasting batteries help minimise waste

+30% extra life since early 2000*

Over the last three decades we’ve constantly increased our battery performance to benefit you, and be kinder to the environment, by reducing unnecessary waste.

*IEC AA Digital Camera test vs. 2004 Duracell Premium

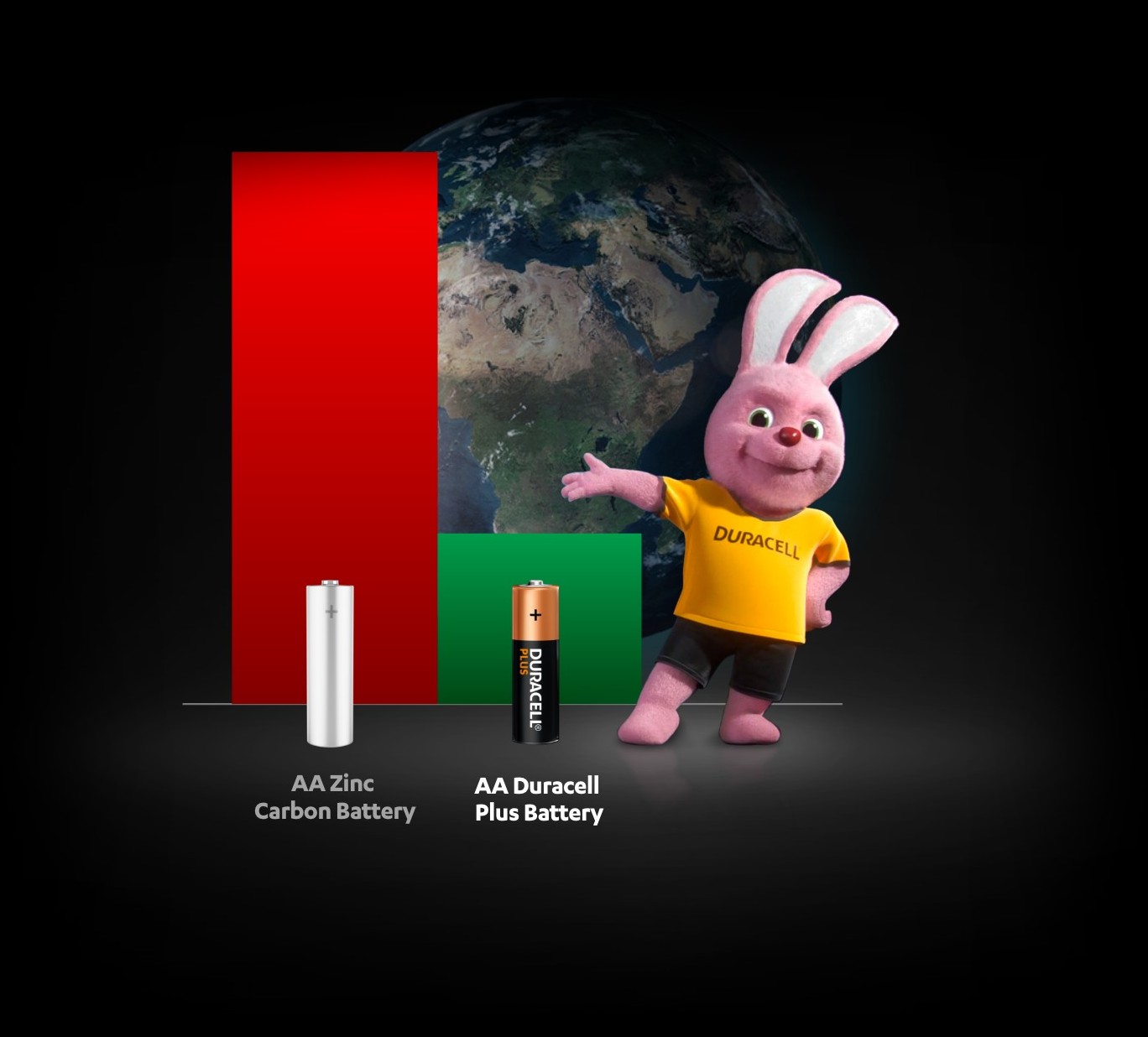

Better performing batteries are better for the environment

Up to 69% lower environmental impact*

*2021 Life Cycle Assessment, conducted by Quantis , Paris. Measured against 6 recommended indicators by the Product Environmental Footprint Category Rules for Battery (PEFCR): Climate Change, Fossil Energy, Mineral & Metal Depletion, Water Consumption, Particular Matter, Acidification

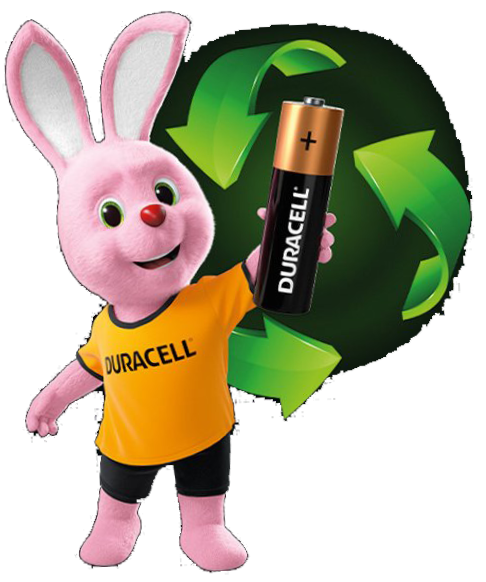

Recycling

Empty batteries

still contain value

Recuperated valuable raw

materials used for:

Source: BEBAT Belgium

PROMOTING RECYCLING INITIATIVES AROUND THE WORLD

In the UK, Duracell’s ‘Big Battery Hunt’ incentivises school children to find the used batteries hiding in their households.

- Working with 2500+ schools

- 300 tonnes of batteries collected for recycling

- After the initiative, 92% of pupils were more likely to recycle batteries showing a positive impact in recycling behaviours†

Big Battery Hunt’s Impact Measurement Report (2018)

Similar to the UK initiative, our German 'Batterie Challenge’ has had great results in promoting greater recycling of batteries

- 98 schools and around 26,000 pupils have taken part

- 176 tonnes of batteries collected for recycling from all over Germany

Products

Technology

About Us

Help and Support

Copyright © Duracell Inc. All rights reserved.

Want to learn about batteries for the B2B market?

If you want to find out more about Procell, the professional brand of the Duracell company, click continue to Procell. If not, click back to Duracell or close this window.